Building-integrated photovoltaics - impressive performance of all involved

The planning phase

Innovative BIPV facade design by AVANCIS - insights into the design process

Our design team, lead by Melicia Planchart, has launched a pioneering initiative for building-integrated photovoltaics (BIPV) with the DHL solar facade project. This ambitious project, which involved cladding the facade of a parking garage with solar panels, demonstrates that AVANCIS is at the forefront of advancing sustainable architectural practices. Our team's workflow is completely digitized. Custom BIPV design tools combine parametric design, optimization algorithms and energy simulations. In this way, we combine aesthetics with energy optimization, enabling building envelopes that are visually captivating while maximizing energy yield.

Streamlining the shape and optimizing the design

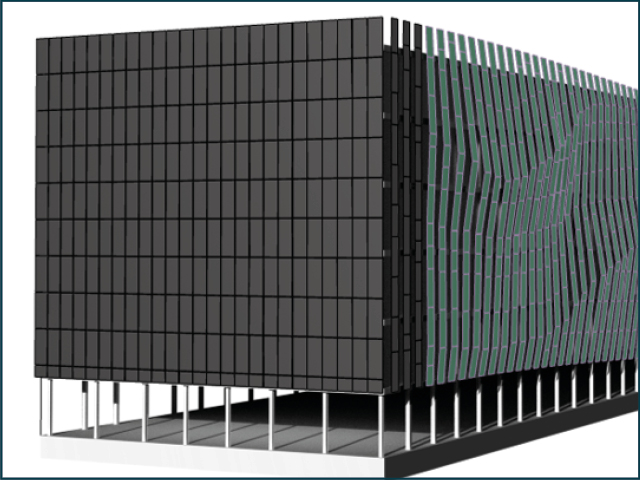

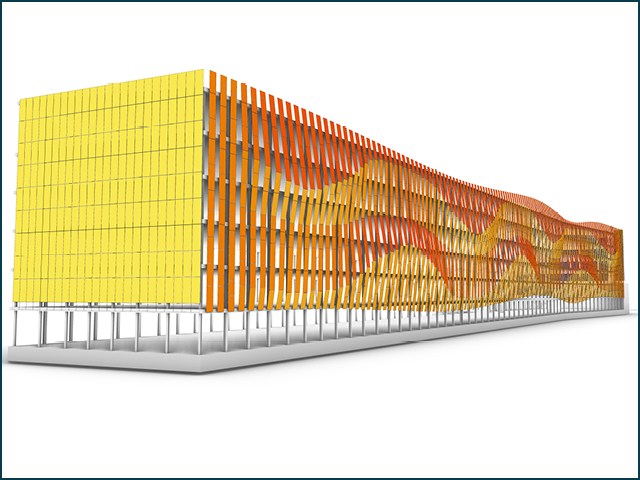

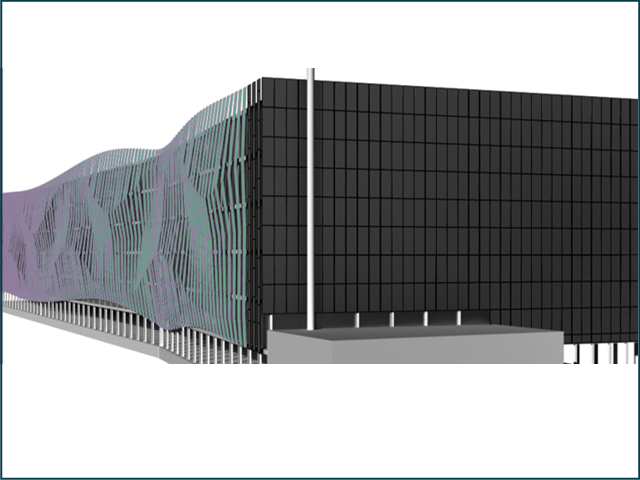

At the beginning of the design process, the shape of the facade was refined and optimized to balance aesthetics with technical requirements and to ensure that the solar panels could adapt to the shape. This included simplifying the geometry of the original concept and reshaping the design to match the orientation and angle of the solar skin. The proportions and orientation of the curves were adjusted using generative design and genetic algorithms to improve the appearance and use of solar energy.

Optimization of substructure and module sizes

The goal of the substructure design was to determine the optimal number of different support points required for the solar skin, thereby reducing the number of custom elements and maximizing the number of standardized ones. Similarly, when optimizing the modules, our team focused on standard sizes and a minimal number of small, passive modules to optimize cost and energy yield while maintaining the characteristic flow and movement of the facade.

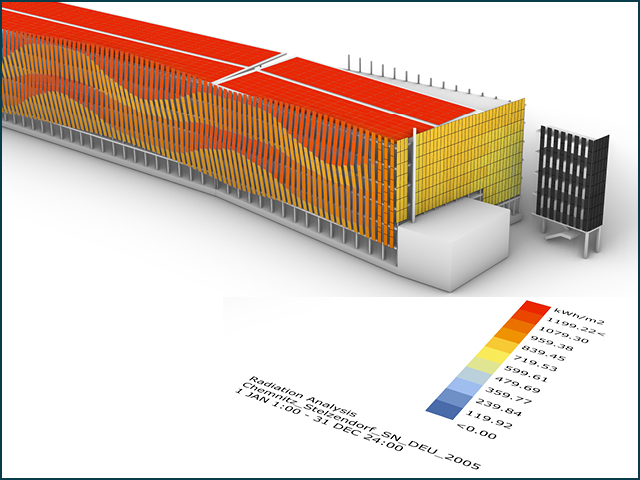

Simulation of the energy yield

Extensive simulations were used to determine the positioning and tilt of SKALA modules to ensure effective utilization of solar energy. Our innovative approach sets a new standard for sustainable façade design by seamlessly integrating advanced digital calculation tools, energy simulations and aesthetic principles.

The construction phase

Contract conclusion

After the final conclusion of the contract in April 2023, the PV application team of AVANCIS, lead by Michael Körner, took over the coordination of the construction site. As in several successful projects before, the company elektroBAU Dresden was engaged as subcontractor for the demanding installation services. The main task of the PV application team was to implement the specifications of the planning, coordinate the material deliveries, coordinate the interfaces with other trades, supervise the installation work, participate in the official project meetings with the client and prepare the documentation for the overall system certification. The assembly of the solar modules began on June 12.

Roof area coverage with silicon solar modules

In the first phase, the roof surfaces of the NetOps buildings were covered with 62 Jetion modules and the parking garage with 1,005 Jetion modules. These are monocrystalline silicon modules from our sister company Jetion, which is also part of the large CNBM family. The DHL parking garage is thus our first hybrid large-scale project in which we combine facade and rooftop installations on one building.

Facade design with BIPV solar modules SKALA

At the end of June, module installation began on the west facade of the parking garage, followed by the south facade. The final stage was the assembly of the east facade, including the cladding of the south staircase on the Aerologic building. The complete module assembly was then completed on August 22. A total of 2,032 black and green SKALA modules were installed on the facades. Despite a delayed start of assembly of more than eight weeks caused by the construction site, we were able to meet the deadlines originally agreed in the contract.

Project launch

In the coming weeks, the solar modules will now be wired and the roof of the Customs building will be completed with 240 Jetion modules. The commissioning of the complete facade and roof system is planned for the end of September. After more than five months of construction, we can assess that the interaction between all parties involved has worked excellently and thus the completion could take place on time. We therefore look forward with a clear conscience to the official opening date of the campus on September 4.

The project support

From the basic idea, through the planning phase, to the construction phase, our Director of Sales & Marketing Augustin Rohr was a driving part of the project. Between the bidding phase and the conclusion of the contract, he acted as an intermediary between the client and the architects, assisted in exploring the various options, feasibility studies and coordinated the teams involved as well as possible external service providers.

With the help of our strong project teams from the various departments, we as AVANCIS were able to realize a project of this magnitude. We combined the skills and strengths of the individual colleagues to ensure a smooth project flow and delivered on-time completion in the end.

We will continue to use the experience gained from this project for future projects in order to provide our customers with successful complete BIPV solutions. On the way to a more environmentally friendly future, the DHL project should serve as a beacon of inspiration beyond the borders of Saxony and inspire sustainable architectural design.